Introduction to Class C Fire Extinguishing Agents

When dealing with electrical fires, understanding the proper suppression methods becomes crucial for safety and effectiveness. Do class C extinguishing agents come in bulk containers? Absolutely, and this method offers significant advantages for fire safety professionals. Class C fires involve energized electrical equipment, making them particularly challenging to handle compared to other fire classifications. These fires require specialized extinguishing agents that can safely suppress flames without conducting electricity or causing additional hazards.

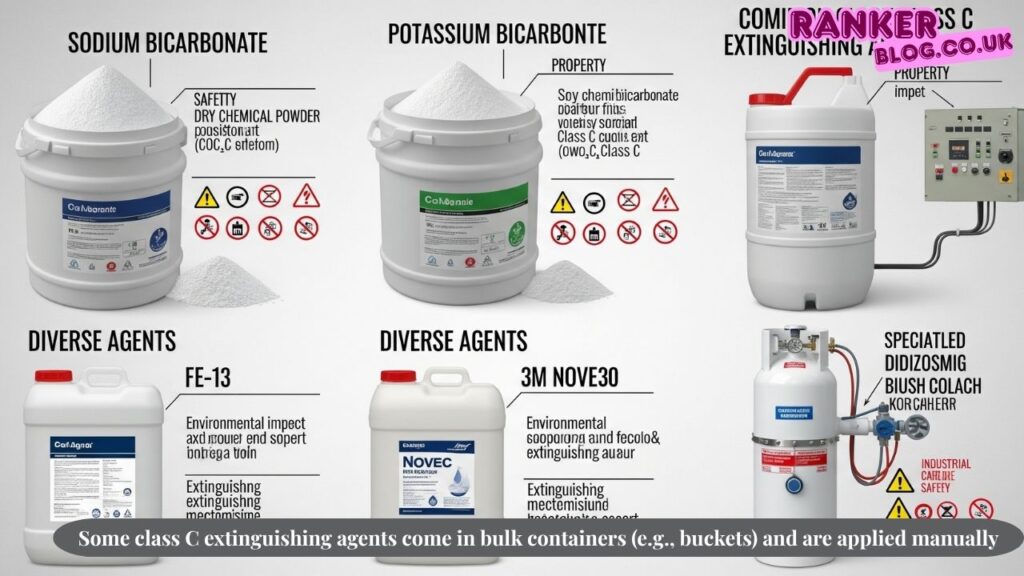

Some class C extinguishing agents come in bulk containers (e.g., buckets) and are applied manually, offering fire safety professionals an alternative to traditional pressurized systems. This manual approach provides flexibility and cost-effectiveness in various industrial and commercial settings where automated systems might not be practical or economically viable.

The classification system for fires helps determine the most appropriate suppression method. Class C fires specifically involve live electrical equipment, requiring non-conductive extinguishing agents to prevent electrocution risks. Understanding this classification ensures that responders select the correct suppression method and avoid potentially dangerous mistakes during emergency situations.

Safety considerations for electrical fire suppression extend beyond simply choosing the right agent. Responders must consider power isolation, approach angles, and personal protective equipment to minimize risks during suppression activities. The manual application method introduces an additional layer of complexity that necessitates proper training and preparation.

Bulk Container Systems

Industrial facilities and commercial buildings often utilize bulk container systems for their fire suppression needs. These systems typically involve large containers such as drums, bins, and specialized buckets designed to hold significant quantities of extinguishing agents. The containers come in various sizes depending on the facility’s specific requirements and risk assessment.

Understanding that class C extinguishing agents come in bulk containers helps facility managers make informed decisions about their fire suppression strategies. Storage requirements for these systems include climate-controlled environments to maintain agent effectiveness and prevent degradation. Proper ventilation ensures that any residual vapors or particles don’t accumulate in storage areas.

Environmental considerations play a crucial role in selecting and placing bulk containers. Facilities must ensure that storage areas remain dry, temperature-controlled, and easily accessible during emergencies. The location should also provide adequate space for safe maneuvering during agent retrieval and application.

The advantages of bulk storage systems include reduced per-unit costs, simplified inventory management, and the ability to handle larger fires or multiple incidents without running out of suppressing agent. These systems prove particularly valuable in industrial settings where electrical fires might be more frequent or extensive.

The cost-effectiveness of this approach becomes evident when facilities calculate their long-term operational expenses. Bulk systems eliminate the need for regular pressure testing, valve maintenance, and periodic replacement of pressurized cylinders, which are characteristic of traditional fire suppression equipment.

Manual Application Methods

Direct application techniques require trained personnel to approach electrical fires systematically and safely. The manual method involves using appropriate tools to distribute the extinguishing agent effectively across the fire area while maintaining safe distances from energized equipment.

Proper approach angles typically range from 45 to 90 degrees to the fire source, allowing for optimal agent coverage while keeping the operator at a safe distance from potential electrical hazards. Distance considerations vary based on the voltage involved and the specific extinguishing agent being used, but generally maintain a distance of at least six feet from energized equipment.

Safety protocols during manual application include establishing communication with electrical technicians when possible, ensuring backup personnel are available, and maintaining clear evacuation routes. These protocols help protect both the person applying the agent and other personnel in the vicinity.

Personal protective equipment requirements encompass electrical-rated gloves, non-conductive footwear, flame-resistant clothing, and respiratory protection when necessary. The specific PPE selection depends on the facility’s electrical systems and the particular extinguishing agents being used.

Common Bulk Class C Extinguishing Agents

Dry chemical powders represent the most common type of bulk extinguishing agent for electrical fires. Sodium bicarbonate and potassium bicarbonate formulations provide excellent fire suppression capabilities while remaining non-conductive. These powders work by interrupting the chemical reaction that sustains combustion.

Clean agents available in bulk form offer advantages in sensitive electronic environments where residue cleanup might be challenging or expensive. These agents leave minimal residue and cause less damage to electronic equipment compared to traditional dry chemical suppressants.

Many facilities ask “do class c extinguishing agents come in bulk containers” when considering carbon dioxide systems. Some Class C extinguishing agents come in bulk containers designed specifically for carbon dioxide application, although this requires special handling procedures due to the gas’s properties. Carbon dioxide displaces oxygen around the fire, effectively smothering the flames, but requires a careful application to prevent asphyxiation risks.

Sand and other inert materials serve as backup options in situations where specialized agents aren’t available. While not as effective as purpose-designed suppressants, these materials can help contain smaller electrical fires by smothering and providing thermal absorption.

Operational Procedures

Pre-application safety checks form the foundation of a successful electrical fire suppression system. When possible, isolating power to the affected equipment eliminates the electrical hazard and allows for more aggressive suppression tactics. However, many situations require suppression while the equipment remains energized.

Application techniques vary depending on the type of electrical equipment involved. Motors, transformers, and control panels each present unique challenges that require adapted approaches. Understanding these differences helps ensure effective suppression while minimizing damage to equipment.

Coverage patterns focus on creating a blanket effect that surrounds and penetrates the fire area, providing comprehensive protection. Even distribution prevents re-ignition while ensuring that all potential fuel sources receive adequate coverage with the suppression agent. Proper technique requires practice and understanding of how different agents behave during application.

Post-application procedures include monitoring for re-ignition, ventilating affected areas, and beginning cleanup operations. These steps help prevent secondary fires and prepare the area for damage assessment and potential equipment restoration.

Advantages and Limitations

Manual bulk systems offer several benefits that make them attractive for specific applications. The flexibility to apply agents exactly where needed, combined with the ability to continue application for extended periods, provides significant advantages over fixed systems with limited capacity.

Limitations of these systems include response time delays and the requirement for trained personnel to be present during emergencies. Some class C extinguishing agents come in bulk containers (e.g., buckets) and are applied manually, which means human intervention is always required, potentially slowing initial response times.

Situations where manual application proves preferable include areas with limited access for fixed systems, locations where automated systems might cause unnecessary damage through false activations, and facilities where maintenance costs for computerized systems would be prohibitive.

Training requirements for operators involve understanding electrical safety, proper application techniques, and emergency response procedures. Regular practice sessions help maintain proficiency and ensure that personnel can respond effectively during actual emergencies.

Safety and Regulatory Considerations

OSHA and NFPA guidelines provide the regulatory framework for electrical fire suppression activities. These standards encompass a range of topics, including personnel training requirements, equipment specifications, and emergency response procedures. Compliance ensures both legal protection and operational safety.

Electrical safety protocols require coordination with facility electrical personnel whenever possible. Understanding the electrical systems involved helps responders make informed decisions about approach methods, equipment isolation possibilities, and potential hazards.

Agent-specific health and safety concerns vary depending on the suppression materials being used. Do class C extinguishing agents come in bulk containers with special handling requirements? Yes, many do, and understanding these requirements helps prevent health risks and ensures a practical application.

Documentation and reporting requirements enable facilities to track incidents, assess response effectiveness, and pinpoint areas for improvement. Proper documentation also supports regulatory compliance and provides valuable data for future emergency planning and response.

Maintenance and Storage

Agent quality control involves regular testing to ensure that bulk materials maintain their effectiveness over time. Moisture absorption, contamination, and chemical degradation can all affect suppression capabilities, making routine testing essential for reliable performance.

Container maintenance includes regular inspection for damage, proper sealing, and cleanliness. Damaged containers can allow moisture infiltration or contamination, rendering the extinguishing agent ineffective when needed most.

Shelf life considerations vary among different agent types, with some materials remaining effective for years while others require more frequent replacement. Understanding these timeframes helps facilities maintain fresh, effective suppression materials without unnecessary waste.

Inventory management procedures ensure adequate quantities remain available while preventing excessive stockpiling of materials that might degrade over time. Regular inventory rotation helps maintain fresh supplies and identifies any storage issues before they become problems.

Also Read: When Summarizing the of a Plot, One Should Notice the Key Ideas About How the Conflict Builds